HB078-1-04S3-M6J

HYBRIFLEX™ Direct LTE, Cabling Solution for 3 RRU

Rev : B | Rev date : 12 Aug 2014

RFS' HYBRIFLEX™ cabling solution for Remote Radio Unit (RRU) combines optical fiber and DC power in a single lightweight aluminum corrugated cable, making it the world's most innovative solution for RRU deployments. It was developed to reduce installation complexity and cost at Cellular sites.

HYBRIFLEX™ cabling solutions allows mobile operators deploying RRU architecture to standardized installation process and eliminates the need and the cost for an internal grounding wire.

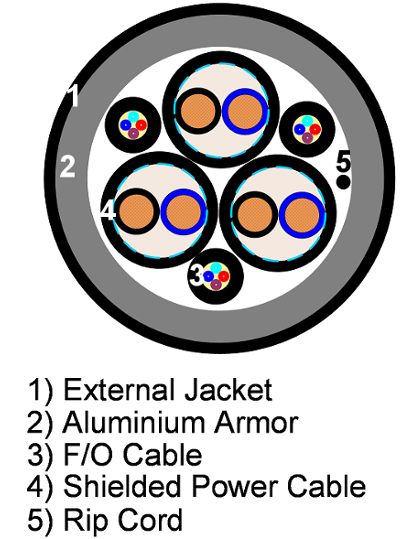

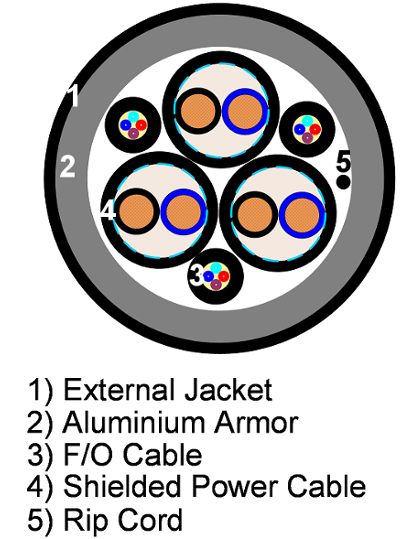

The HYBRIFLEX™ cable is part of a site installation kit. It consists of an armored bundle of 3 shielded DC cables, 3 F/O distribution cables and a rip cord to adjust the breakout part of the cable.

FEATURES / BENEFITS

- A corrugated armor with excellent bending characteristics minimizes installation time and enables mechanical protection and EMC shielding

- Outer conductor grounding eliminates typical additional grounding requirement and saves on installation costs

- Lightweight solution and compact design decreases tower loads

- Robust cabling eliminates need for expensive cable trays and conduits

- Installation of stripped fiber optic cable pairs directly to RRH reduces CAPEX and wind load by eliminating need for junction boxes

- F/O and DC housed in single corrugated cable saves CAPEX by standardizing RRH cable installation and reducing installation equipments

HYBRIFLEX Series

Structure |

|---|

| Cable Type | | 3 RRU HYBRIFLEX™ Direct LTE | | Size | | 7/8 | | Fire Performance | | Halogene Free |

|

Mechanical Specifications |

|---|

| Outer Diameter Nominal | mm (in) | 27.8 (1.09) | | Cable Weight | kg/m (lb/ft) | 0.76 (0.51) | | Minimum Bending Radius, (Operating) | mm (in) | 120 (4.7) | | Minimum Bending Radius, (Installation) | mm (in) | 250 (9.8) | | Tensile Strength | N (lb) | 700 (157) | | Recommended / Maximum Clamp Spacing | m (ft) | 0.8 / 1 (2.75 / 3.3) |

|

DC Power Cable Specifications |

|---|

| Number of DC Pairs | | 3 | | Maximum DC-Resistance Power Cable | Ω/km (Ω/kft) | 4.95 (1.51) | | Cross Section of Power Cable | mm² (AWG) | 4 (12) | | Shielding | | braid | | DC Wire Jacket Material | | Polyethylene, PE, Metalhydroxite Filling | | DC Wire Jacket Thickness | mm (in) | 0.5 (0.02) | | DC Cable Single Bending Radius | mm (in) | 100 (3.94) | | DC Cable Diameter | mm (in) | 9.9 (0.39) | | DC Cable Jacket | | UV stable black PE | | DC Standards (Meets or Exceeds) | | IEC 60229 |

|

Cable Jacket |

|---|

| UV-Protection Individual and External Jacket | | Yes | | Jacket Material | | UV stable black PE |

|

Armor Specifications |

|---|

| Armor Type | | Corrugated Aluminum tube | | Maximum DC-Resistance of Armor | Ω/km (Ω/kft) | 1.21 (0.37) | | Copper Equivalent Cross Section of Armor | mm² (AWG) | 16 (5) | | Diameter Corrugated Armor | mm (in) | 25.2 (0.99) |

|

F/O Cable Specifications |

|---|

| F/O Cable Type | | Tight-Buffer, Multimode | | Number of F/O Pairs | | 6 | | Core/Clad | µm | 50 /125 | | Secondary Protection Nominal | µm (in) | 900 (0.035) | | Single Bending Radius | mm (in) | 50 (1.97) | | Cable Diameter mm (in) | | 4.8 (0.19) | | F/O Cable Jacket | | UV stable black PE | | F/O Standards (Meets or Exceeds) | | IEC 60793-2-10 |

|

Testing and Environmental |

|---|

| Storage Temperature | °C (°F) | -40 to 85 (-40 to 185 ) | | Operation Temperature | °C (°F) | -40 to 85 (-40 to 185 ) | | Installation Temperature | °C (°F) | -20 to 50 (-4 to 122 ) | | Jacket Specifications | | not applicable | | LSZH Specification | | not applicable |

|

Product Detail